Has something gone wrong recently in the milk bottling industry? Someone taken their SixSigma training too far? I don’t know what’s happened, but suddenly I find myself in need of sharp implements to open my milk when the convenient pull-tab on the seal is somehow no longer very convenient.

It’s a classic ‘if the only tool you have is a hammer, every problem looks like a nail’ issue I think. That plus the bigger issue of the way process engineers (and actually all of us) have been taught. When the process engineer is trying to get the seals to stick on the top of the bottle, there aren’t many process variables they can play around with. The main one in fact is how much glue to place between the rim of the bottle top and the seal. As soon as this becomes the case the only available hammer then becomes the Goldilocks and the Three Bears strategy: Not too much glue, not too little. And the desire to find ‘just the right amount’.

This is classic optimization territory. But it is also bad news from the customers point of view because it leads the designers to do dumb things. Not putting enough glue on the bottle is worse news than putting too much on. If the milk leaks, everyone complains, but if the seal needs a knife or fingernail to get it off, the customer is probably frustrated but not sufficiently to actually write an email (or blog article!) to complain about it. Consequently, ‘just the right amount’ of glue tend to err on the side of too much.

Then, of course, the process engineer knows there is variation in the glue dispensing system. So that gets cunningly compensated for too. More glue. Not so good from a cost perspective, but definitely better than those troublesome customer complaints about leaking bottles. Just more annoying seal-removal frustration.

What’s so idiotic about this whole scenario is that the designer thinks they’ve done a good job. They used maths. They did their Design of Experiments. They drew a distribution curve. They worked out their safety margin. They ‘proved’ they’d done the best they could possibly do. They were taught – SickStigma Black Belt-style – how to optimize a situation that wasn’t actually an optimization problem.

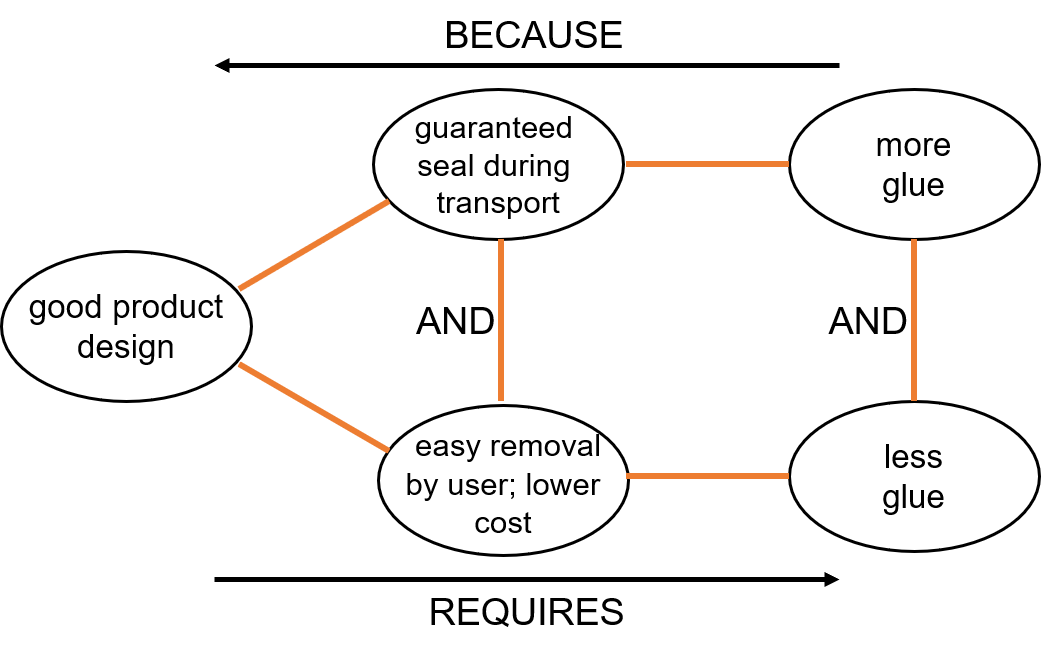

When you find yourself playing Goldilocks, it ought to be a pretty good indicator that you’re working on the wrong problem. Goldilocks was an optimizer. Smart people recognise there’s no such thing as ‘just right’ and instead look to solve the contradiction. Which in this case is ‘we want more glue AND we want less glue’. Something like this:

Now at least we’re working on the right problem. The ‘best of both worlds’, solve-the-contradiction problem. Now we have some chance of making progress. And not have to have thousands of customers spend time fishing out fragments of broken seal and excess glue from their milk.

I have just rewatched your TRIZ and first principles webinar. I thoroughly enjoyed it – again – so thank you for doing it. You mentioned that you might do more, I wondered if you have?

I have not seen contradictions explained using the conflict cloud very often. I like the way you have drawn this one, guided with ‘requires’ and ‘because’ notations.

Goldratt believed that 70% of undesirable effects in a system could be linked to a core conflict (contradiction). I wondered if you had a view on that in respect to complex systems, like human and process dynamics within an organisation?

Hi Jimmy, thanks for the feedback. We spend a lot of our time working on complex systems in organisations and society. My view is 1) there is no such thing as a ‘root-cause’ in a complex problem; 2) there may be a ‘root contradiction’; 3) there are likely to be several root contradictions. Not sure if you subscribe to the SI ezine, but there’s the start of a complex-systems case study on Fake News in this month’s issue – http://systematic-innovation.com/current-e-zine.html – that should give you a clue or two about how we deal with this kind of complex problem. Best, darrell