No-one goes to work intent on doing a bad job. W. Edwards Deming taught me that. I also believe that merely arriving at work with an intention to do good things does not mean that good things will inevitably happen. Deming taught me that too. Sometimes, very well intentioned people do an incredible amount of harm.

Like, for example, the people tasked with writing Standards.

I was once on a Committee tasked with writing an International Standard. Every time I went to one of the meetings I used to get a knot in my stomach. At the time I didn’t know why. In the end, I made my apologies and left. I never really understood the reason either for the knots or the departure.

More recently, I’ve been in the position of watching other people participate in the Standard writing process. The forthcoming ISO18404 to be precise. A Standard that is designed to regulate the Lean, SixSigma and ‘Lean & SixSigma’ markets. Under normal circumstances I’d watch the emerging shambles with a wry smile on my face. There are only so many ills one person can get themselves worked up over. And, in theory at least, a Lean and/or SixSigma Standard ought to have nothing at all to do with innovation. One might go so far as to say they are the very antithesis. In practice, however, I have a sneaking suspicion ISO18404 will do even more damage to the world of innovation that it inevitably will to the Lean and SixSigma communities.

What I know about Standards in general and ISO18404 in particular is that they have been established because ‘someone’ has realised that as industries grow they invariably attract rogue elements. Encourage enough Lean practitioners into the consulting market, in other words, and sooner or later it will begin to fill up with consultants that don’t really know what they’re doing.

These rogue elements, therefore, the well-intentioned Standards Committee members conclude, need to be weeded out. Good ones will be ISO18404 ‘Certified’ and, bad ones will not meet the regulated competencies (of which there are 23 in the case of Lean) and hence won’t be certified. So much for the theory. So much for helping wary prospective clients from hiring a ‘bad’ consultant.

The first question that needs to be asked, I think, is how much harm ‘bad’ consultants actually cause? We saw the ‘bad consultant’ problem in the TRIZ world in several countries for a while a decade ago. Idiots that go on a two-day TRIZ course and then think they’re qualified to solve nuclear fission problems for clients. It was a problem for the TRIZ world for about a year, and it was a problem for prospective clients – the real customer – for about a day.

In one particularly memorable (as in ‘I still bear the emotional scars’ way) experience, we had a client that insisted they wanted to go through a ‘real’ ARIZ session. So we found them a real TRIZ Master (Certified by Altshuller himself), and helped set the workshop up. The Russian TRIZ Master told us the session would need three days. At the end of the first day, the client pulled me over on one side and said, ‘don’t worry, we’ll of course pay you for all three days, but, please, we need to end this here’. It had taken them a day to realise that TRIZ ‘Master’ or not, they were in the presence of someone that had absolutely no ability to empathise in any way with a room full of restless engineers.

In reality ‘bad’ consultants aren’t a real problem at all for clients. If the client is looking to, say, embark on a Lean journey, the most likely thing they’re going to do is put out a Request For Proposals. Lots of Lean practitioners will see these proposals, and the least busy will very likely submit proposals.

At the moment none of these proposals will show any kind of Standard accreditation. This is a little bit inconvenient for the client, because it means they are actually going to have to read the proposal. That’s probably going to cost about half an hour. If it’s a really bad consultant, though, they will very likely be found out at this stage. If it’s a more cunning bad consultant, they might get past this first down-select. They might get to a point where they are invited to turn up and talk face-to-face with the client. Another couple of hours gone, but it’s pretty difficult for incompetent people to hide their incompetence for more than an hour when someone is looking them in the eye. When someone lies about their past track record, a simple phone call to references will pick up the problem. And even if the bad consultant prevails through this evaluation and gets the job, their incompetence will be found out within a couple of days of starting it.

Put frankly, if a prospective client isn’t able to weed out bad consultants very quickly and very easily, they deserve all they get. Call it a self-organising system. Idiots deserve idiots. Its exactly the same situation as when clients choose their consultants on the basis of price and it goes wrong: the failure is annoying, but at least they learned something important: choosing on today’s ticket price is a dumb way to go about any kind of business.

Here’s what a Standard will do in the above scenario: a) clients will look for the ISO badge and as soon as they see it will tend to stop reading the proposals and – worse – stop thinking (this is called ‘plausible deniability’ – when things go wrong, they can now shrug their shoulders, point their boss to the ISO logo, and say, what else could I have done?’), b) the self-organising nature of the industry becomes progressively destroyed and everyone – clients and consultants – become more interested in the badge than thinking about the actual need, c) before too long, the whole charade descends into a ‘badge collecting’ industry. Good consultants waste time administering their ongoing Certification evidence; bad consultants spend theirs working out how to subvert the system. See ISO 9000 for a good example of what this looks like when the system is properly ‘mature’.

It’s a bad thing that this happens. Even worse that it appears to be universal.

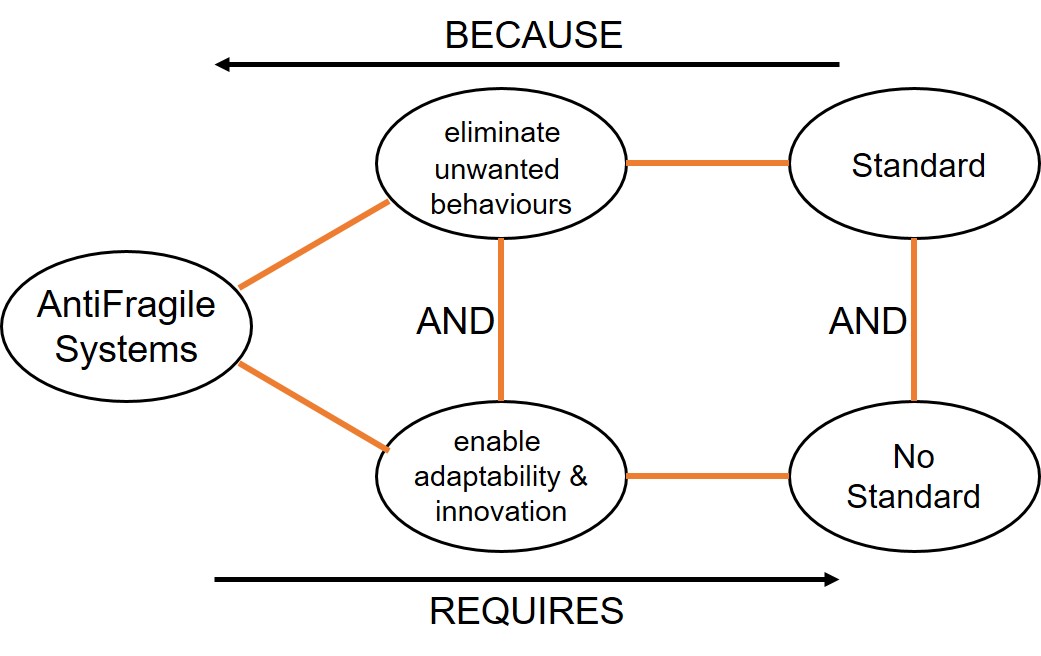

But it’s not the worst thing. The worst thing is that the well-intentioned Standard-writing do-gooders have only ever looked at half the story. They (naively) see a ‘bad practice’ problem and decide they had to fix it. But they never look at the other side of the coin. Standards do good things, but they also do bad things. Standards are, by their very nature Contradictions: ‘We want a Standard and we don’t want a Standard’. We want Standards (in theory) to weed out the ‘bad’; we don’t want them because they impede the ‘good’.

And in the case of ISO 18404, the specific ‘good’ I think they’re inadvertently about to kill is innovation:

Standards lock in today’s practices and impede advances. They stop people thinking, and as a consequence they become a ready-made excuse to not innovate. That’s what I see. I’ve had this argument several times with Standards people. ‘Ah, yes,’ they will say to me, ‘but we review the Standards every three years’. To which my answer is why three years? What happens when the world pulses at a rate faster than three years… as is the case in most industries today.

But even this is the wrong argument to get into – we should always know that if a question contains the word ‘or’ in it, it’s the wrong question. It’s not about should we review a Standard every three years or every six weeks. The right question is ‘how can we have a Standard AND not a Standard?’

Now, I admit that I’ve never met a Standards person yet that understands what the hell I’m talking about when I use this kind of TRIZ language. Sometimes I even try to tone my language down a bit. ISO18404 – like every other Standard before it – kills innovation because no-one has done anything to cater for the down-side. Maybe I don’t need to mention ‘contradictions’, maybe instead, all we need to do is get Standards people to think about the likely negative consequences of their actions and to build a solution to these consequences into the Standard.

Its not even that its hard to do this, it simply means that people have to give themselves permission to think about the down-sides and incorporate something into the Standard to prevent them from happening.

In the case of ISO18404, for example, it would have been very, very easy to include a twenty-fourth competence that ‘Good’ Lean or SixSigma or ‘Lean & SixSigma’ practitioners would have to demonstrate their abilities against:

‘Practitioners need to be able to demonstrate that they understand the limits of the Standard, and that they do not encourage or endorse client solutions that will impede the innovation ability of the client’.

That’s called ‘solving the contradiction’.

It’s time for another Standard, I believe. A Standard for Standards writers. A Meta-Standard. A Standard that prevents Standards from turning into value-destroying industries that serve only the officials they employ. It probably only needs two clauses:

Clause 1: the system should be designed in such a way that it emerges in a progressively self-organising manner, that will eventually eliminate the need for the Standard.

Clause 2: whenever an either/or Contradiction emerges that hinders the achievement of Clause 1, Standards Committees should devise solutions that eliminate such Contradictions.

The only downside, I suppose, is that it will kill the Standards-writing industry. And then where would the ‘bad’ consultants go and work?